Shaken, not stirred

Deep vibro compaction is used under the foundations of buildings. The method is used to improve the ground and thus compensate for soils with low load capacity. Our Vertical Sky® A 32 turbine for certification also uses this method. It serves to improve the ground and thus compensate for soils with low load capacity.

In addition to road construction, the preparation of pre-assembly areas is one of the first steps in the construction of the Vertical Sky® A 32 certification turbine.

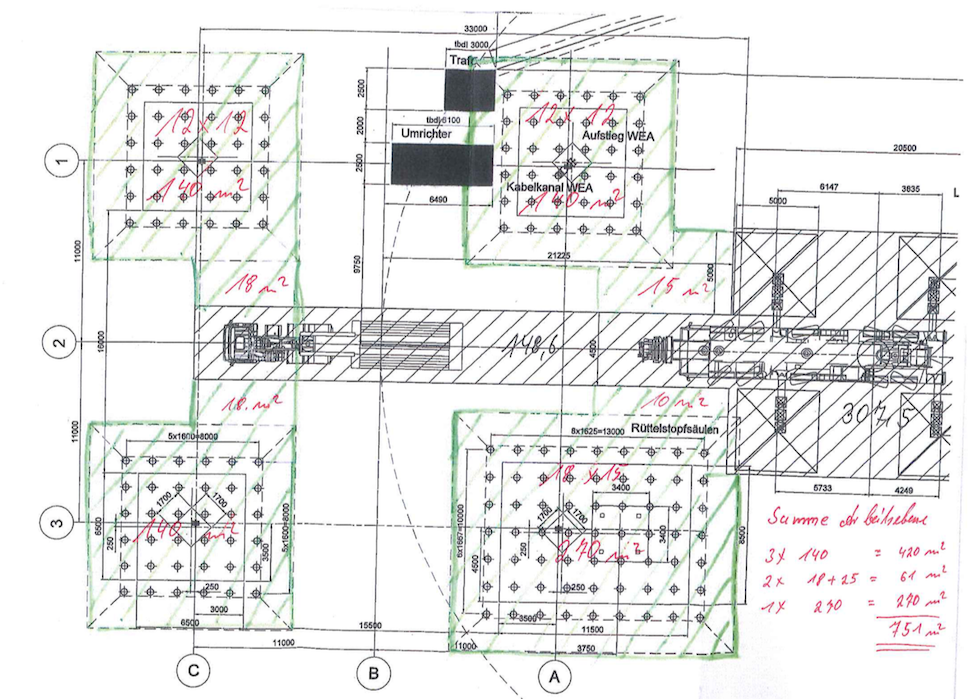

Drawings on the exact location of the vibro stone columns are calculated by a soil surveyor. The pink crosses on the bottom are the centers of each stone column.

Load- bearing columns are made from gravel or crushed stones. For the whole process the workers needed a less than a week.

The depth vibrator can be between 3 m and 5 m and weigh up to 2 tons.

The depth vibrator displaces the soil laterally during drilling. The cavity is then filled, creating a column with gravel.

Before drilling can begin, a level working area for the vibrator tamping device must be prepared.

On the right is the device for the production of the columns. A wheel loader delivers the waste material into the hopper of the machine. This is pulled up at the gray iron pipe from the hopper. There, the ballast material is filled into the tube and brought by shaking in the ground and compacted.