advantages

Vertical Sky® –the quietest wind turbine in the world

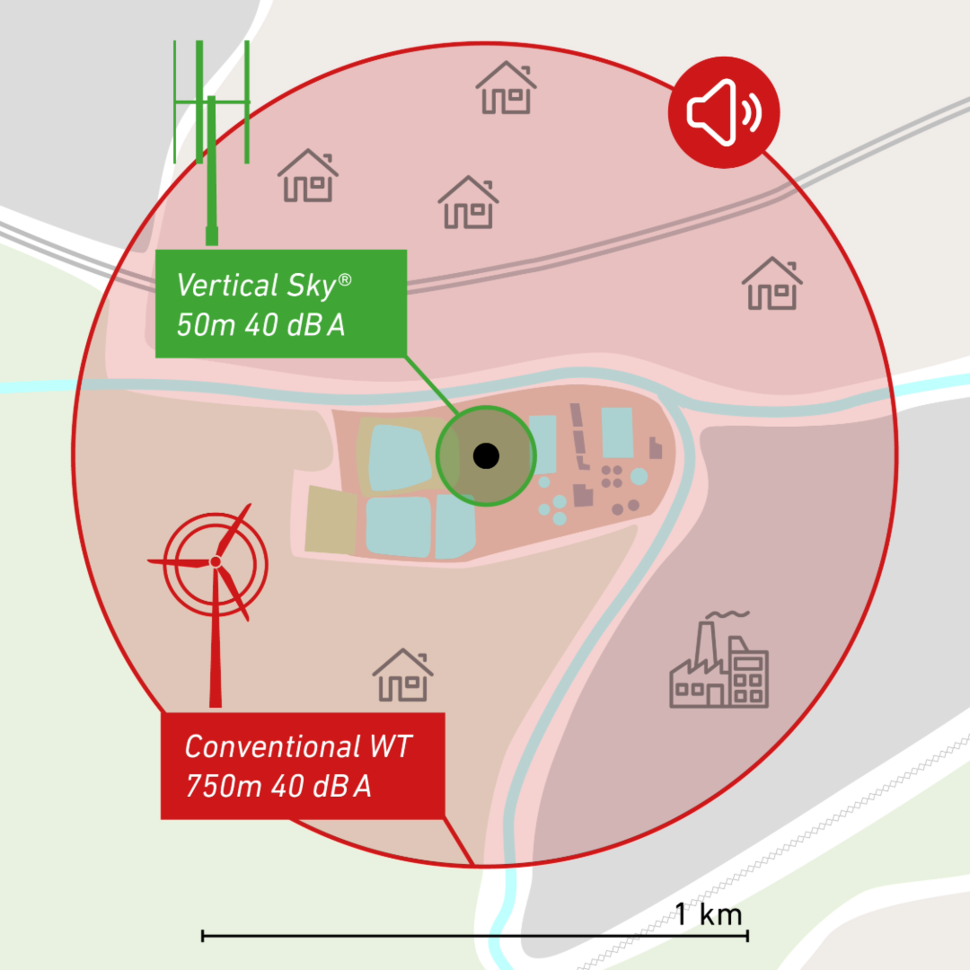

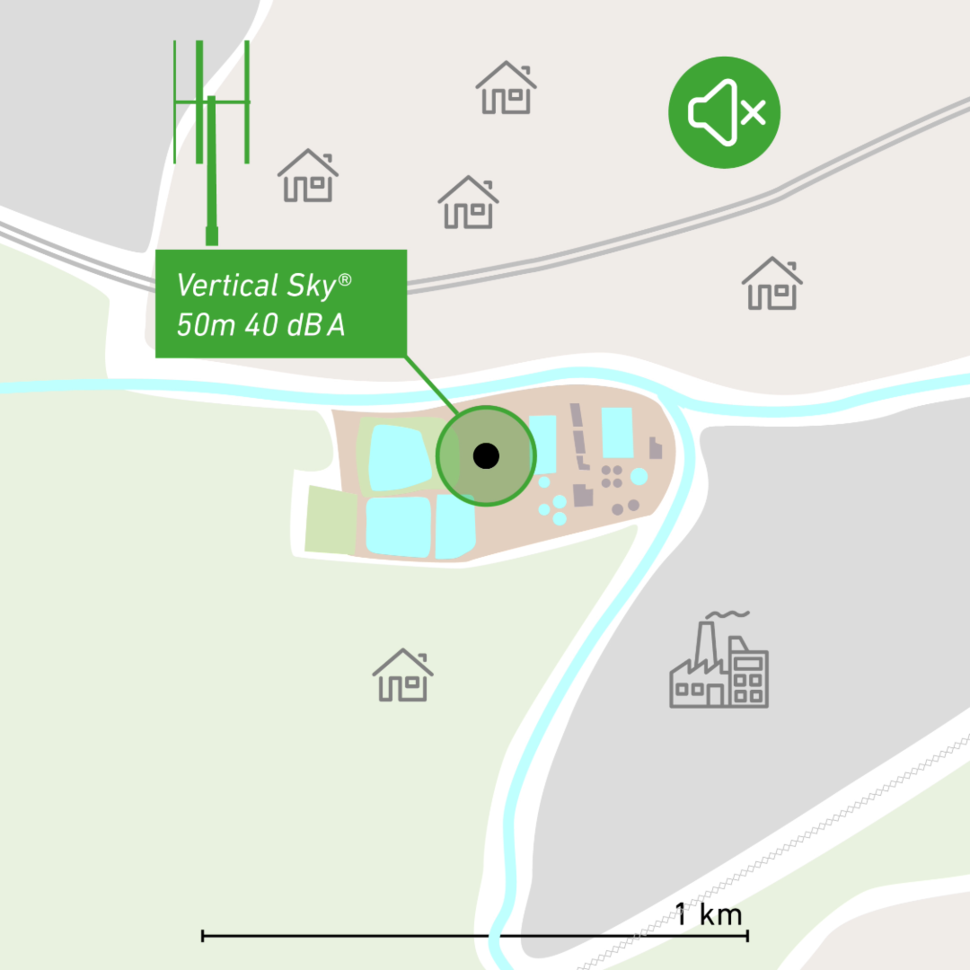

Due to the extremely low noise emissions and the easy logistics for transport, installation, operation and maintenance a high environmental compatibility is guaranteed. As a result, Vertical Sky® can be installed near populated areas. Thus, it is also possible to develop difficult terrains, in which existing technologies cannot be used. This is the main reason why Vertical Sky® is interesting for distributed power supply.

Generate power where it is needed.

The Vertical Sky® wind turbines are characterised by a lower rotational speed compared to conventional wind turbines. This reduced speed minimises aerodynamic noise emissions considerably and enables particularly quiet operation.

*The stated 35 dB refer to a distance of 100 metres from the turbine.

This low-noise characteristic makes the Vertical Sky® turbine ideal for use in industrial areas. There, it can generate renewable energy directly on site and thus contribute to the sustainable power supply of industrial plants. Decentralised energy production reduces transmission losses and increases the efficiency of the use of renewable resources.

Reduced operation costs ensure a high economic efficiency. The light components enable an easy transport without considerable field damages. Furthermore, a Vertical Sky® wind turbine needs neither oversize transport nor special mobile cranes. A convenient installation system preserves the resources of mankind and nature.

An investigation carried out by the SBB (Swiss Federal Railway) has shown that the potential area to be used for wind farming is four times bigger with Vertical Sky® compared to traditional wind turbines.

Vertical Sky® - where others can't get to.

In countries with previously untapped potential for decentralised energy supply, the Vertical Sky® from Agile Wind Power is an interesting alternative. Due to its advantages, the turbine may be installed and operated in the direct vicinity of factories, communities or industrial plants. It can be seen as an addition to conventional wind energy plants in regions that cannot be served with conventional technologies.

The rotor blades are ready laminated and prepared for the finishing work. Our professionals for the production of the composite parts have years of experience in the construction of conventional wind turbines.

ADVANTAGES

The significant advantages of Vertical Sky®

Low visual impact

(integrated appearance)

Maintenance without

special equipment

Almost soundless

(significantly less noise emissions)

Shorter project implementation times

(easier approval process)

Reduced risk for

birds and bats

Better use of space