Product Development

Everything according to plan during demonstrator production

Image: Laminating mold for a section of the rotor blade.

The research and testing facility represents an important step in the development of the commercial systems. It has the same functionality and components as the future 1 MW series turbines and will be erected near Winterthur in September. This plant also serves as an ideal demonstrator for the new technology and allows the topic of wind energy to be experienced in practice.

The electrical engineering, the brains of the wind turbine, is now also being transported to Germany and assembled with the mechanical parts, so that the entire system can be mounted in the hall to ensure efficient assembly on site.

Images: The rotor blades are produced using the laminating process. This is the same process used to produce conventional wind turbines. Our employees have many years of experience in this field.

Purpose of the research and testing facility

_The turbine will be erected near Winterthur in September and will serve as a prototype for the future commercial 1 MW turbines.

_It has the same functionalities and components as the large turbines.

_It enables practical experience to be gained with the new wind energy technology.

Current status of production

_Production of the demonstrator, called Vertical Sky® A6, is proceeding according to plan.

_The rotor blades are currently being laminated at the production facility in Germany.

_A new process for joining the two blade shells is being tested in order to improve stability and increase production speed.

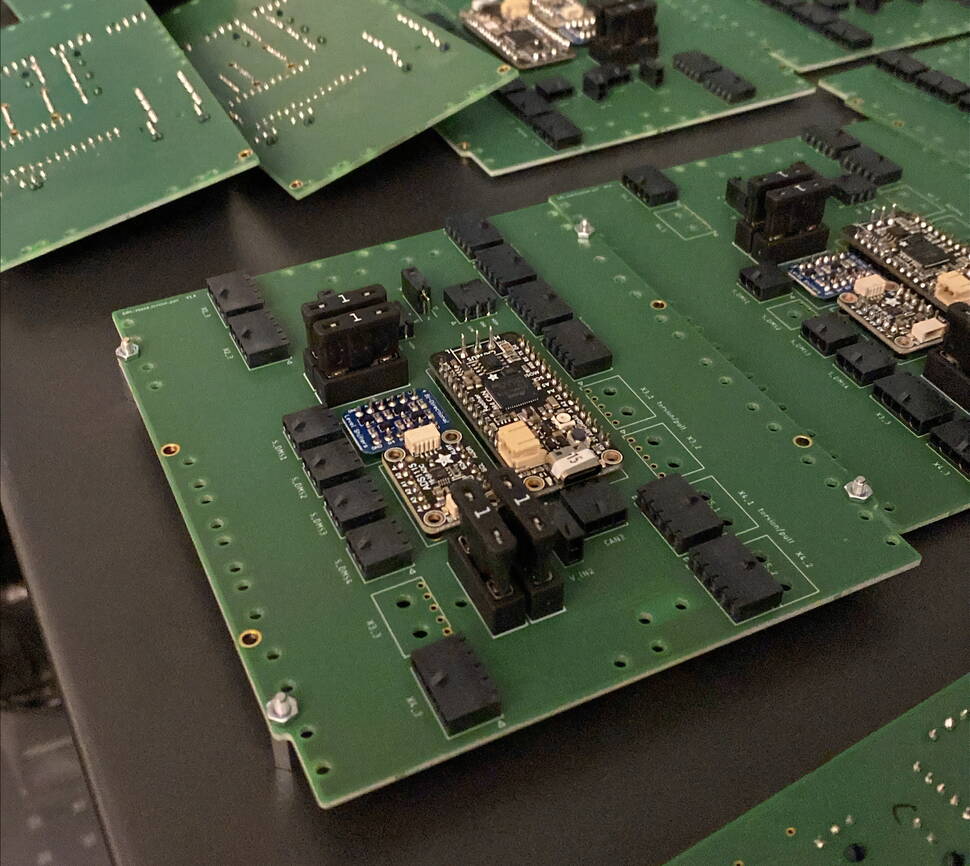

Image: The entire electrical engineering, which is responsible for all the signals from the various sensors and the control of the individual rotor blades, has already been further developed and assembled in Dübendorf.

Electrical engineering

The entire electrical engineering, which is responsible for controlling the rotor blades and processing the sensor signals, was functionally expanded and assembled in Dübendorf, and this electrical engineering is transported to Germany to be assembled there with the mechanical parts of the wind turbine, thus ensuring efficient assembly of the entire system on site.

The demonstrator turbine is not only used for research and testing, but also as a practical example to demonstrate the technology and benefits of wind energy. Careful planning and advances in production as well as innovative technology should ensure the efficiency and stability of future wind turbines.