The Rotor

The last main components of the Vertical Sky® are being completed

At our production site in the former aircraft hangar in Lemwerder (Germany), the production of the rotor for our certification turbine Vertical Sky® is in its final stage. The rotor consists of three rotor arms and three 54 meter long rotor blades. These are the main last components in the production of our first ever Vertical Sky® wind turbine.

The production of the rotor arms

Self-made molds for the rotor arm production

Finishing work on a rotor arm

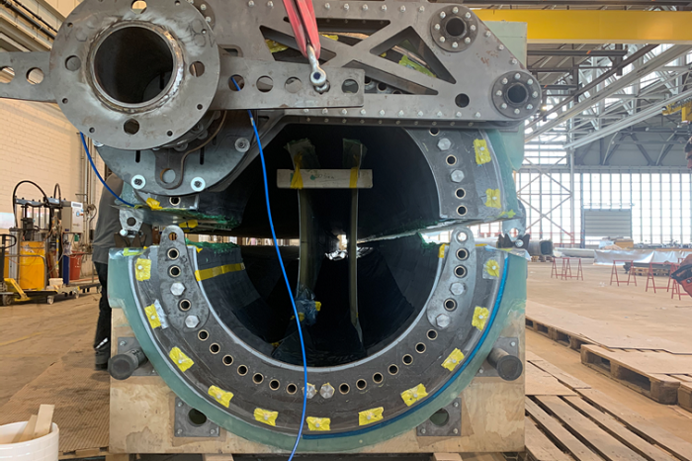

The finished rotor arms for the Vertical Sky® are ready for use

The aerodynamic shells for the rotor arms

The production of the rotor blades

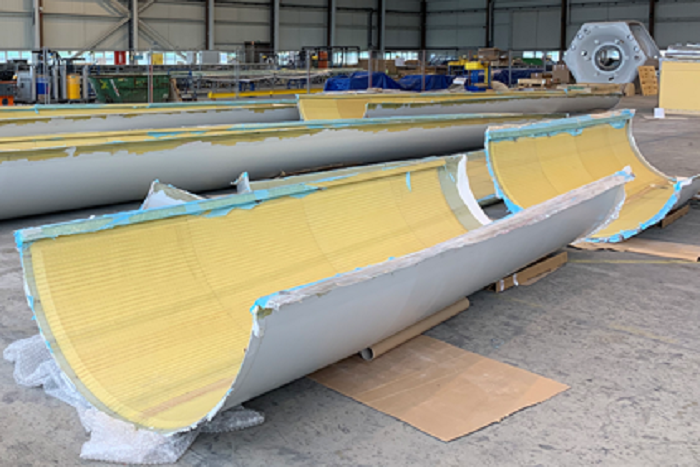

These are the shapes for the rotor blades where the 27-meter-long blades are manufactured. Two such rotor blades will later be assembled into a 54-meter-long rotor blade.

The members of our manufacturing team are covering the mold of the rotor blade with a layer of fiberglass.

Very well visible here is one half of the rotor blades in its mold. In the middle, the blade shaft.

Here a frontal view of the raised rotor blade

The two rotor blades halves are being positioned above each other

Shortly before the two halves of the rotor blades are bonded together

The rotor blade is being lifted out of its mold and transported to its storage space.

Agile Wind Power’s productions site in the former aircraft hangar in Lemwerder near Bremen (Germany).

Despite the ongoing pandemic, the original time schedule is being adhered to and we expect to receive the rotor on time for the assembly on the construction site.

Our Vertical Sky® can soon be built together, put into operation, and get certified!